Home fire safety tools are designed to reduce risk — but not all tools work the same way. One of the most important differences between fire suppression products is whether they are pressurized or non-pressurized.

Understanding how each approach works, and where each fits best, helps households build a safer and more realistic fire safety plan.

What Does “Pressurized” Mean in Fire Suppression?

Pressurized fire suppression products store extinguishing agents under pressure, typically using:

- Compressed gas

- Chemical propellants

- Mechanical pressure systems

When activated, the stored pressure forces the agent toward the fire.

This approach is common in:

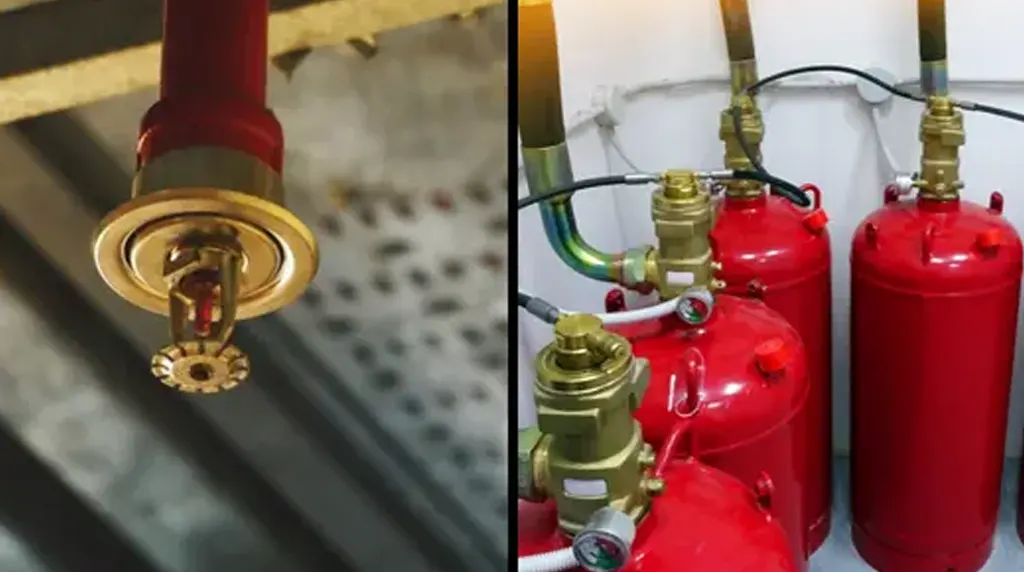

- Traditional fire extinguishers

- Industrial and commercial fire systems

- Environments with trained users and maintenance routines

What Does “Non-Pressurized” Mean?

Non-pressurized fire suppression products:

- Do not store energy under pressure

- Remain inert during storage

- Activate only when exposed to fire or high heat

They rely on:

- Heat-triggered reactions

- Passive or low-energy activation mechanisms

This design leads to different safety and handling characteristics.

Key Differences at a Glance

Aspect | Pressurized Suppression | Non-Pressurized Suppression |

Stored pressure | Yes | No |

Mechanical complexity | Higher | Lower |

Maintenance needs | Periodic checks required | Typically minimal |

Activation | Manual, immediate discharge | Heat-triggered or simple activation |

Storage sensitivity | Affected by temperature and damage | Generally more tolerant |

Training dependency | Higher | Lowe |

Safety Considerations in the Home

1. Stored Energy Risk

Pressurized systems contain stored energy at all times. While designed to be safe, they:

- Depend on seals and valves

- Can degrade if improperly stored

- Require regular inspection

Non-pressurized systems eliminate this stored-energy factor entirely.

2. Ease of Use Under Stress

In a home fire:

- Users may be untrained

- Stress levels are high

- Reaction time is limited

Simpler activation methods may reduce hesitation or misuse in early-stage situations.

3. Long-Term Storage

Many household fire safety products:

- Sit unused for years

- Are stored in cupboards, garages, or vehicles

- Experience temperature fluctuations

Non-pressurized products may offer advantages where routine inspection is unlikely.

Where Pressurized Suppression Excels

Pressurized systems remain essential when:

- Fire size exceeds early-stage limits

- Rapid agent delivery is required

- Certified fire class ratings are needed

- Professional or trained users are present

They are a cornerstone of traditional fire safety.

Where Non-Pressurized Suppression Fits Best

Non-pressurized products are often suited to:

- Early-stage incidents

- Confined spaces

- Supplementary protection near risk points

- Households seeking reduced complexity

They are designed to complement, not replace, pressurized extinguishers.

How to Choose the Right Approach for Your Home

There is no single fire suppression solution that fits every household.

When planning home fire safety, consider:

- Likely fire risks in the home

- Who would respond in an emergency

- Training and familiarity with equipment

- Storage conditions and maintenance habits

Many homes benefit from using both approaches, each serving a different role.

Fire Safety Works Best as a Layered System

Fire safety professionals consistently emphasize that:

- No single product prevents all fires

- Different tools address different stages of risk

- Preparation and understanding matter most

A layered approach may include:

- Smoke alarms for early detection

- Certified fire extinguishers for larger incidents

- Fire blankets or non-pressurized suppressants for early-stage response

- Clear escape plans and regular family awareness

Each layer reduces risk — none replaces the others.

Avoiding False Confidence

One of the biggest fire safety risks is overconfidence.

Whether pressurized or non-pressurized, suppression tools:

- Have defined limits

- Work best under specific conditions

- Cannot guarantee outcomes

Understanding those limits improves safety more than assuming protection.

Final Thoughts

Pressurized and non-pressurized fire suppression systems are not competitors — they are different tools designed for different roles.

Pressurized systems remain essential for many fire scenarios.

Non-pressurized systems offer practical advantages in certain home environments, particularly for early-stage incidents and long-term storage.

The safest homes are not the ones with the most equipment — they are the ones with the best understanding of how and when to use it.

About ZUFF

ZUFF develops non-pressurized, compact fire suppression solutions designed to help address small, early-stage fires in modern home environments.

ZUFF products are intended to complement certified fire safety equipment, not replace professional emergency response.